To live up to our vision and mission, we continue to deliver the energy the world needs today while working on solutions for the future. We are doing this through a dual focus on reducing the environmental impact of our current business, and investing in renewable technologies that support a circular and sustainable economy.

We have decreased average emissions per vessel across our businesses. We are on track to meet the IMO’s environmental goal of a 40% reduction in carbon intensity by 2030 and a 50% reduction in total annual GHG emissions by 2050, compared to 2008 levels.

Our fleet has improved on the industry’s two most prominent measures of carbon intensity: Annual Efficiency Ratio (AER) and Energy Efficiency Operational Index (EEOI). From 2022 to 2023, as an average across our businesses, AER and EEOI improved by 10.7% and 1.3%, respectively.

Retrofitting Existing Assets

In 2023, BW LPG marked three years since the delivery of its first LPG-powered Very Large Gas Carrier (VLGC), the 2015-built BW Gemini. 17 vessels in BW LPG’s fleet now have LPG dual-fuel propulsion technology onboard, allowing us to serve customers with one of the lowest emissions profiles in the sector, with carbon emissions reduced by approximately 27,000 MT or 15% compared to conventional compliant fuel usage.

LPG dual-fuel engines have the potential to reduce emission of Sulfur Oxide (↓97%), Particulate Matter (↓90%), Carbon Dioxide (↓15%), and Nitrous Oxide (↓20%). It means that vessels powered by LPG are in full compliance with current and future Sulfur Oxide (SOx) emission requirements, including for Emission Control Areas (ECAs) and Sulfur Emission Control Areas (SECAs). LPG propulsion also offers efficiency gains on many fronts. Output efficiencies will improve by about 11% with LPG as compared to compliant fuels.

In addition to significant improvement in total voyage fuel economics, other efficiencies include easy storage and faster refueling. Bunkering for the retrofitted vessels can be done with reduced spill risk, either directly at the load terminal or via ship-to-ship transfer from a smaller LPG carrier. The dual-fuel capability also provides fuel flexibility, which translates to fuel system redundancy. Dual-fuel allows for uninterrupted operations and buffers fuel price fluctuations.

LPG dual-fuel propulsion technology has become the sector’s standard, and the preferred method of propulsion by charterers. Our fleet of LPG-powered vessels has increased from 15 to 17, with two dual-fuel newbuilds entrusted to us by our customers.

As we deliver LPG to world markets, we work hard to reduce direct and indirect greenhouse gas emissions from operations, such as through the adoption of new propulsion technologies, as well as in other ways including voyage optimisation, weather routing and Just-in-Time arrivals.

Investing in technological innovations for operational efficiency

In the eightieth session of the International Maritime Organization (‘IMO’) Marine Environment Protection Committee (‘MEPC’ 80) held in July 2023, a revised 2023 IMO GHG Reduction Strategy was adopted with higher levels of ambition and GHG reduction targets. BW Epic Kosan is committed to achieving these targets as early as possible by investing in technological innovations for improving vessel energy efficiency, digitalisation and in improved new-build designs that lower the GHG emissions at sea and in port.

Ultrasonic transducers

Our vessels are being equipped with ultrasonic transducers to keep their propellers clean and reduce bunker fuel consumption. These transducers produce ultrasonic sound waves which create resonance vibrations in the propeller blades, protecting the blade surface from biofouling. Ultrasonic transducers are also being used to keep sea chests clean. Annual bunker savings of approximately 1% are expected.

Yara Marine FuelOpt

One of our vessels with a CPP propeller is fitted with the FuelOpt system from Yara Marine. FuelOpt is designed to find the ideal balance between fuel consumption and vessel speed. Operating with a constant shaft power, the crew can avoid unwanted consumption during harsh weather conditions, while reaping the rewards during good weather. Dynamic pitch and RPM regulation of the CPP propeller ensures the greatest amount of thrust with the least consumption of fuel. An annual saving potential of 8% is expected.

Remote auto-logging sensors

As part of our efforts to reduce emissions while ensuring crew and vessel safety, we have installed remote auto-logging sensors to monitor vessel performance. The live data from the auto-logging sensors enhances performance monitoring, as it improves the data quality over what can be obtained from noon reports, for better evaluation of our vessels’ performance.

Weather routing and voyage prognoses

In addition to the retrofits mentioned thus far, weather routing and voyage optimisation are performed for all our vessels to optimise vessel efficiency. Third-party software is also used by operators and ship staff.

XGIT-Prop coating

The propellers of our vessels are coated with a graphene-based hard fouling release biocide-free coating that will improve the propulsive efficiency and protect the propellers from biofouling. This coating eliminates chances of discharging any biotoxins, silicon oils or microplastics into the sea, and helps in reducing underwater radiated noise. Annual bunker savings of around 1–2% per annum per vessel are expected.

Contracted loaded tip (‘CLT’) propellers with advanced propeller boss cap fins (‘PBCF’)

In 2024, two of our vessels will be fitted with contracted loaded tip propellers with advanced propeller boss cap fins to improve the vessels’ propulsive efficiency. The CLT propeller reduces the tip vortex, and the advanced PBCF reduces the hub vortex downstream of the propeller. Moreover, the under pressure on the suction side caused by a CLT propeller is lower than an equivalent conventional propeller, while the overpressure on the downstream side is much higher. The expected bunker saving is 8% per annum per vessel.

Silicone paints

We use ultra-premium soft-fouling release silicone paints for the hull coating of all our vessels. As a result, our vessels experience reduced resistance at sea, reducing fuel consumption and greenhouse gas emissions by approximately 5 to 6%. Furthermore, silicone paints prevent marine organisms from growing on vessel surfaces due to their smooth surface properties — unlike the toxic chemicals from biocidal paints, which could have adverse impacts on marine life.

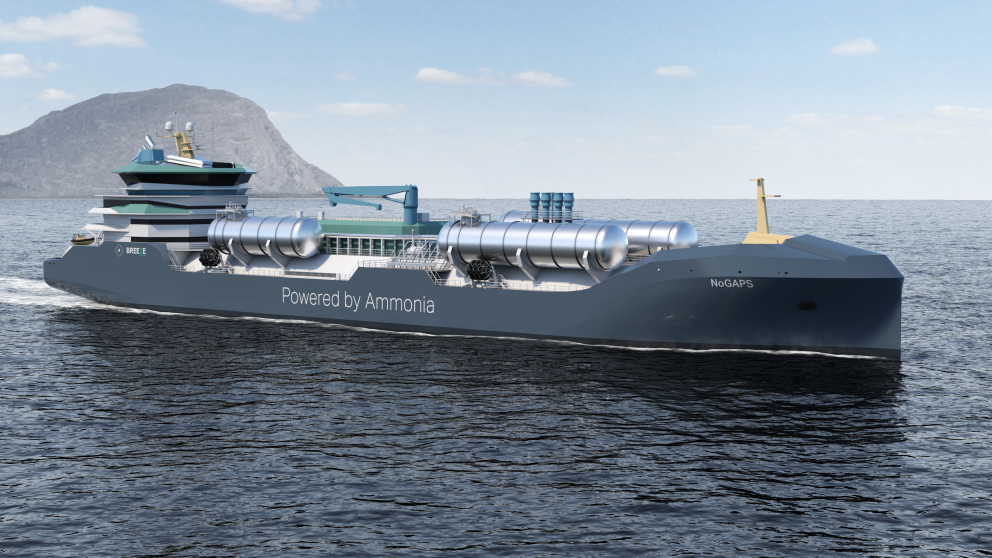

Project NoGAPS

BW Epic Kosan will continue to collaborate with industry partners to support industry decarbonisation efforts. As an example, we are shipping partners in the Nordic Green Ammonia Powered Ships (‘NoGAPS’) project.

The project commenced in 2020 and has brought key industry players together in the value chain for a Nordic-based ammonia-powered vessel. This consortium has elaborated a concept for an ammonia-powered gas carrier, transporting ammonia as a cargo. It has also investigated the vessel, the fuel and the fuelling options, as well as the business and financing considerations.

The first phase was a thorough investigation of new vessel designs, with high safety considerations to minimise the possibility of leaks since ammonia is toxic to people and the environment. The second phase, producing an initial ship design that lays the foundation for a shipyard tender, has been completed. In the third phase, which has now commenced, BWEK has approached several yards for interest and prices.

Concurrently, we are also engaged in discussions with oil majors in relation to carbon capture, utilisation, and sequestration technology.

Safeguarding the environment with technology

We are actively implementing digitalisation initiatives to reduce the environmental impact of our fleet.

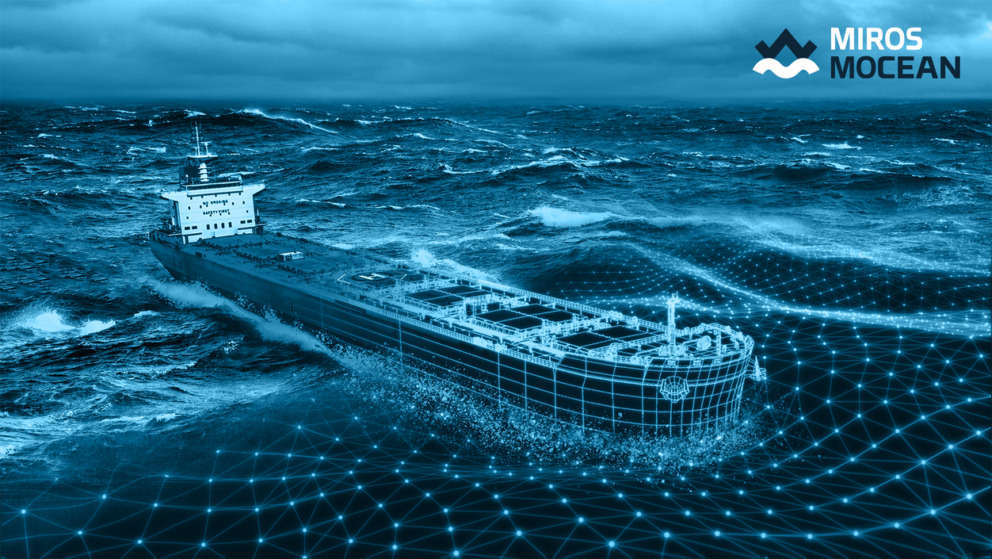

Miros Wavex Technology

The Wavex system provides accurate and reliable wave parameters, including 2D-spectrum, surface current magnitude and direction, as well as speed through water calculations. All these output parameters are key to:

- Enhanced hull and propeller performance management

- Speed optimisation to save fuel

- Reduced cost and risk due to weather claims

- Reduced weather-related vessel and cargo damage

The Miros Wavex Technology provides real-time wave and current monitoring by using data from standard marine X-band radars on vessels or fixed locations. By accurately measuring waves, currents, and vessel speed through water (STW), this marks a step change in vessel performance management. STW measuring devices have until now been unreliable. They cannot accurately predict the current at specific locations and times due to the multi-factorial and high-velocity nature of currents. Instead, speed-overground is typically used. This is despite the inadequacy of SOG in accounting for the complex movement of water.

Today, Miros Wavex technology has overcome these challenges. With accurate STW data, we can now make the right trade-offs between fuel and speed.